Bombas centrífugas magnéticas criogénicas de baja temperatura

Marca DALIAN KEHUAN PUMP

El origen de los productos DALIAN, LIAONING, CHINA

El tiempo de entrega TRES MESES

La capacidad de oferta SUMINISTRO SUFICIENTE

La bomba Kehuan logra un avance integral en el status quo de las bombas magnéticas (como alta potencia, alta temperatura, lodo, fácil vaporización, alto punto de fusión, etc.)

Marco de diseño: utilizamos el modelo hidráulico avanzado europeo;

Estándares de diseño según el estándar API685 del Instituto Americano del Petróleo.

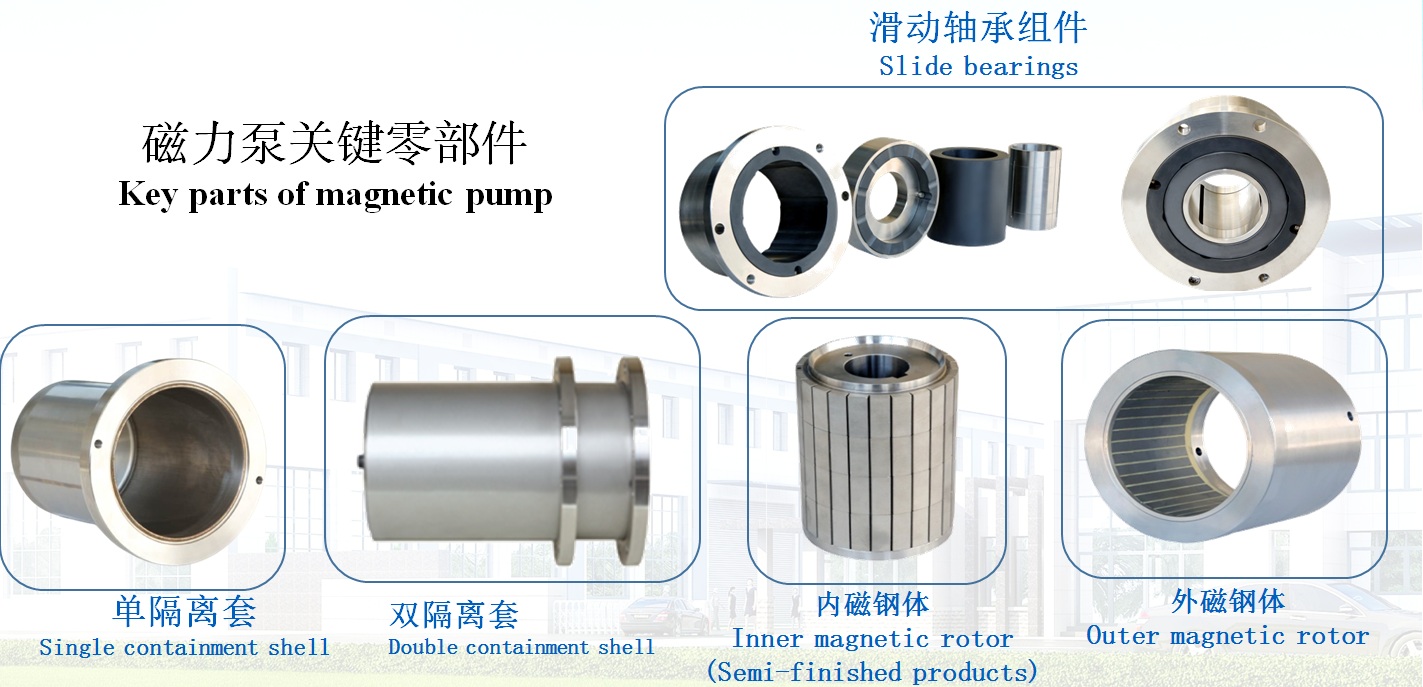

Aplicación de materiales de alto estándar: Imán permanente (Sm2Co17, Temp. -196~450 ℃), Cojinete deslizante (SSIC), Carcasa de contención (HC-276), Cojinete de rodillos (SKF/NSK), Acoplamiento (Wuxi Chuang ming)/KTR alemán ), motor eléctrico (Nan yang/Jiamusi).

Cryogenic Low Temperature Magnetic Cenrtifugal Pumps

Product attributes:

Maximum head :

Maximum fiow:

Driving type:Magnetic

Working Pressure:Middle Pressure Pump

Working impeller number:Single-Stage Pump

Working impeller inlet way:Single Suction Pump

Pump shaft positon:Horizontal Pump

Impeller structure:Closed

Transportation package:Wooden Case

Specification:API685 standard

Trademark:Dalian Kehuan Pump Co.,Ltd

Origin:Dalian,Liaoning,China

Size: DN25~150

Flow(Capacity):0~2000³/H

Temperature: -50~ 100degrees Celsius

Pressure:2.5~10MPa

Power:~560kw

Foot-mounted structure or Center line supported structure.

The pump and motor are separated with standard normal motor, so the pump can be changed parts at site and needs not be returned factory.

The pump hydraulic model is from Europe with high efficiency. Two sets of hydraulic model is equipped at same outlet port. The flow range at BEP best efficiency point is wide.

Leakage-free is realized by static sealing gasket for all the sealing points and magnetic coupling driven. The nitrogen sealing is also not used, so the operation of pump is safe, economic and reliable.

The modular theory design makes compact structure, parts generalization and easy maintenance.

The magnet material is made of special rare earth alloy with demagnetizing temperature up to 450 Degrees Celsius through special technology. So the pumps are guaranteed 15 years of operation life;

The slide bearing material is high purity of 99% silicon carbide, and all the friction couples of bearing are high quality silicon carbide.

The pump standard confirms to API 610, API 685 etc.

Material:

Carbonsteel; chromed steel; austeniticstainlesssteel; duplexsteel; Titanium and Titanium Alloys; Hastelloy C-276 and other special materials; It depends the customer's request.

| PARTS NAME | S-6 | A-8 | D-1 | TITANIUM | HAST C276 |

| Casing | Cast steel | 316 AUS | DUPLEX | Ti | HAST C |

| Impeller | 12%CR | 316 AUS | DUPLEX | Ti | HAST C |

| Containment shell | Hastelloy C276 | Hastelloy C276 | Hastelloy C276 | Hastelloy C276 | Hastelloy C276 |

| Inner magnet rotor | 304/SM2C017 | 316/ | 316/ SM2C017 | Ti /SM2C017 | HAST C/ SM2C017 |

| Pump shaft | 12%CR | 316 AUS | 2205 | Ti | HAST C |

| Slide bearing | 304/SSIC | 316/SSIC | 316/SSIC | Ti/SSIC | HAST C/SSIC |

The containment shell is made fromHastelloy c-276formed by special technology without axial welding seam. So it ensures the sealing and chemical stability for containment shell.

The double layer of containment shell functions reliable double protection. It will be alarmed when the first layer of containment shell is leaked while the medium is still completely sealed without any leakage.

Slide bearing

The material of slide bearing is made from 97.5% purity rate of silicon carbide (SSIC),The working life of the wear resisting and high strength material is 10 times of normal silicon carbide baring and carbon bearing.

Ball bearing

The ball bearing is NSK or SKF bearings.

Lubrication: Grease or Oil, It depends the customer's request

Magnetic material

The magnet material of Kehuan magnetic pump is permanent-magnet alloy with unidirectional temperature up to 450oc. It is a medium to pass on the moment of torsion in magnetic driven pump. It guaranteed a wide

operating range and is highly resistant against demagnetization.